Serving the maritime sector for over 65 years, Çeksan Shipyard launches the chemical tanker M/T AMONITH, equipped with advanced engineering and environmentally friendly technologies.

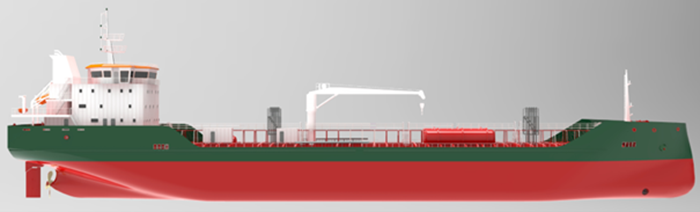

Istanbul-based Çeksan Shipyard has successfully launched the IMO II Chemical Tanker M/T AMONITH (Project NB83). The vessel, built for the Polish shipowner UNIBALTIC, met the water with a ceremony held on Saturday, November 29, 2025. As the final vessel of a special four-ship series, this project stands out with its high local content ratio and superior technical specifications.

The keel of M/T AMONITH was laid in December 2024. Following the launch, the vessel is scheduled to complete its sea trials and be delivered for operations by the end of March 2026.

Developed entirely through R&D and design activities led by Turkish engineers, M/T AMONITH distinguishes itself from its competitors with exceptional efficiency. The hydrodynamic hull structure, originally developed by NORDEN Design, has been further optimized through additional CFD (Computational Fluid Dynamics) analyses, reducing water resistance by 6%.

Thanks to this design success, M/T AMONITH features a propulsion system that is 25% more efficient compared to similar vessels. The ship can reach a maximum speed of 13 knots with a power output of 2800 kW while fully loaded with 8,100 tons of cargo. This capability allows it to transport the same amount of cargo at the same speed with significantly lower energy consumption, resulting in fuel savings and reduced emissions.

Constructed in line with decarbonization goals in the maritime industry, M/T AMONITH holds the eco-friendly "CleanShip" class notation. The project has been built with infrastructure prepared for Methanol (Methanol Prepared), which is regarded as the fuel of the future. Additionally, the vessel is equipped with an SCR system that filters NOx (Nitrogen Oxide) emissions, minimizing its environmental impact.

Other environmental features of the vessel include:

Ballast Water Treatment System: To prevent the transport of invasive marine species.

Cold Ironing (Shore Power): Equipped with a 3x350A transformer capacity and management system to receive 690V or 440V power from the shore, allowing ship generators to be shut down at ports.

Working with the industry's top brands, Çeksan Shipyard achieved a 45% local content ratio in this project. The vessel is certified under "Dual Class" by both Bureau Veritas and Türk Loydu.

In terms of safety, the ship features a fully automated engine room. The PTI (Power Take In) feature on the shaft generator allows the vessel to be propelled by power obtained from the ship's generators in emergencies, such as a main engine failure. The cargo tanks are constructed from Duplex 2205 stainless steel, capable of handling heavy acid cargoes with a specific gravity of 1.86 ton/cbm.

Vessel Name: M/T AMONITH

Owner: UNIBALTIC (Poland)

LOA (Length Overall): 117.9 m

Beam: 17 m

Depth: 9 m

Design Draft: 6.6 m

Cargo Capacity: 4 Segregations

Speed: 13 knots (Max) / 11 knots (Economic)

Propulsion Power: 3000 kW

Generators: 3 × 445 kW + 1 × 950 kW shaft alternator

Class: Bureau Veritas & Türk Loydu (Dual Class)